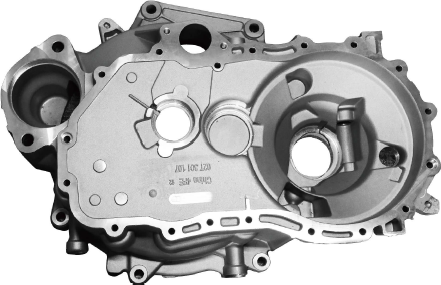

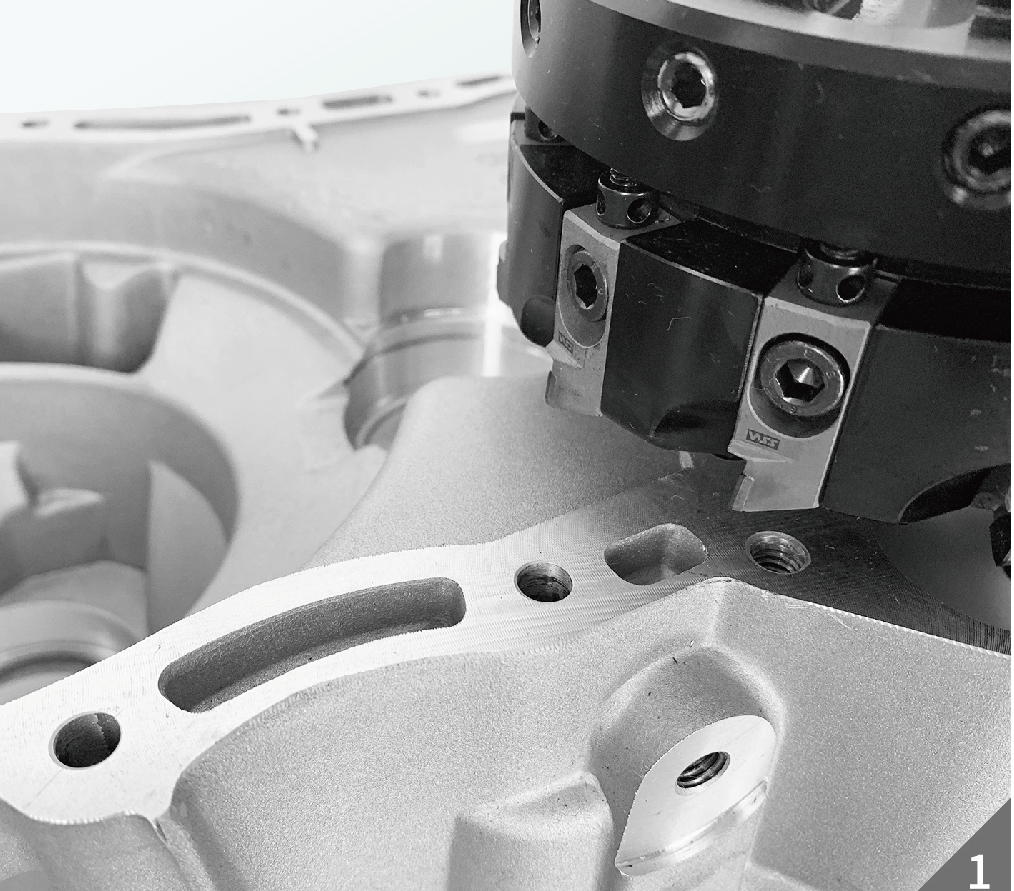

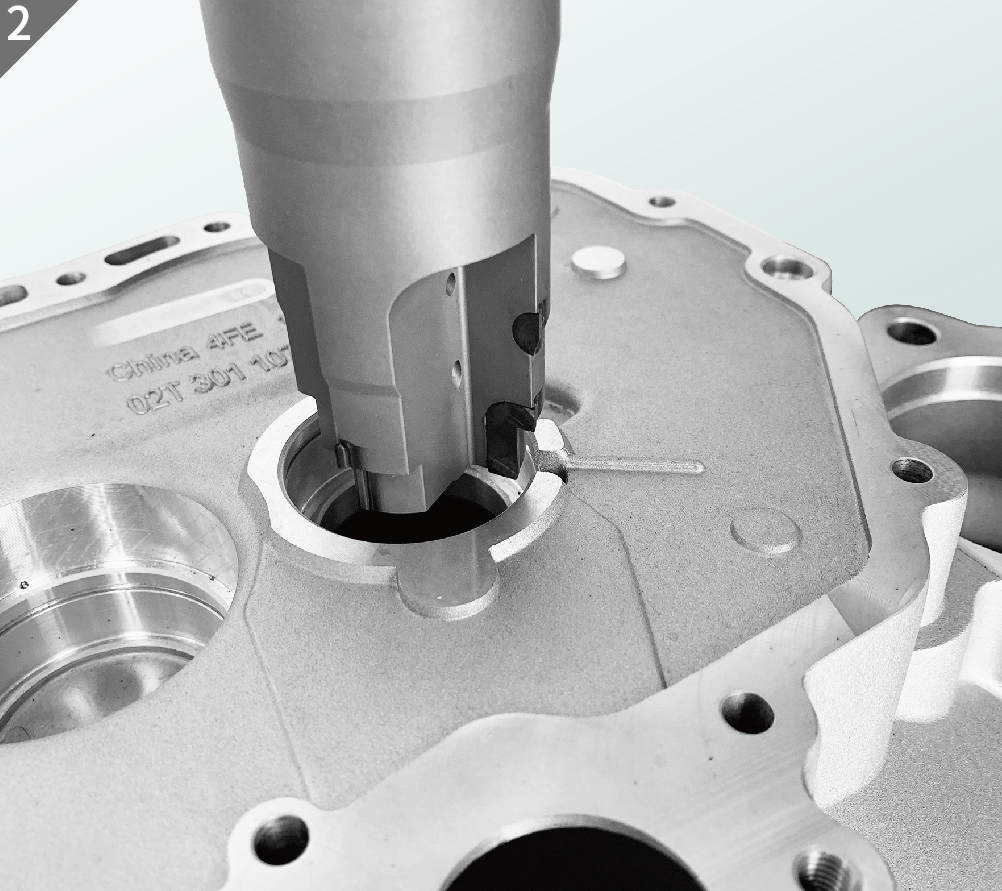

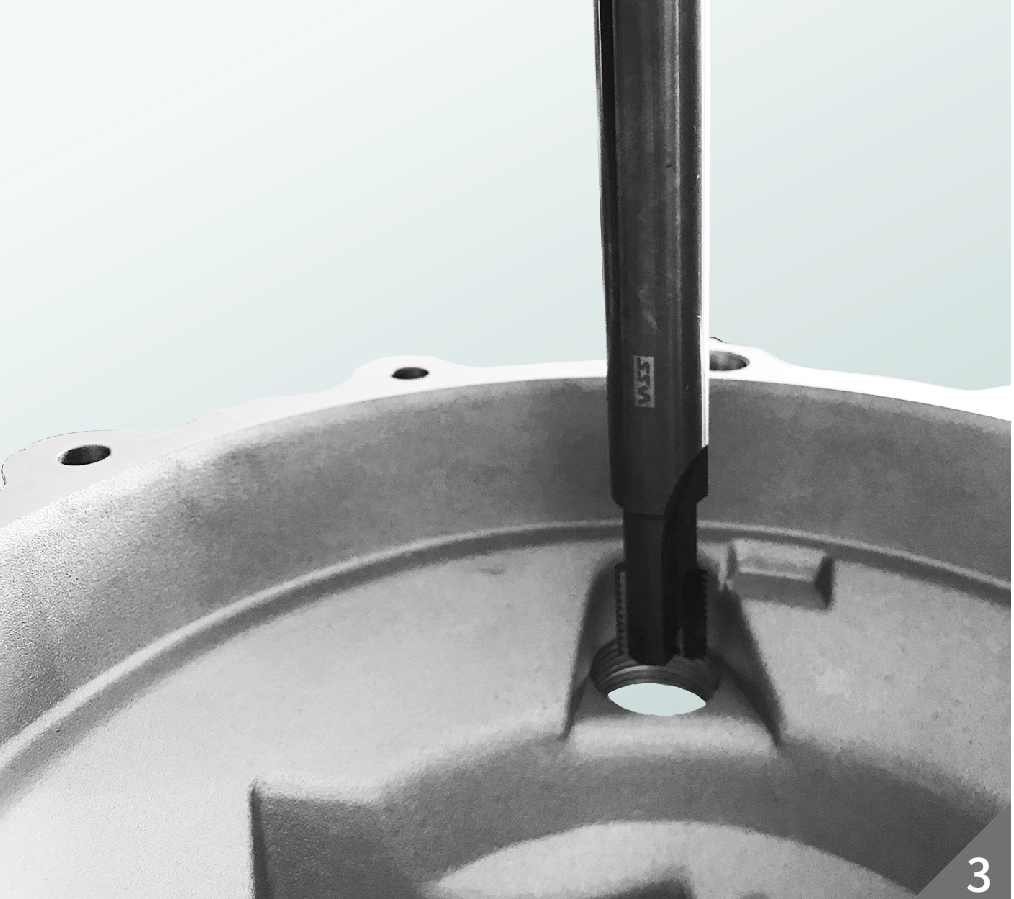

- Transmission

- Turbochargers

- Automotive steering accessories

- Pistons

- Brake Calipers

- Valve seats

- Clutch discs

- Sprockets

- Oil distribution discs

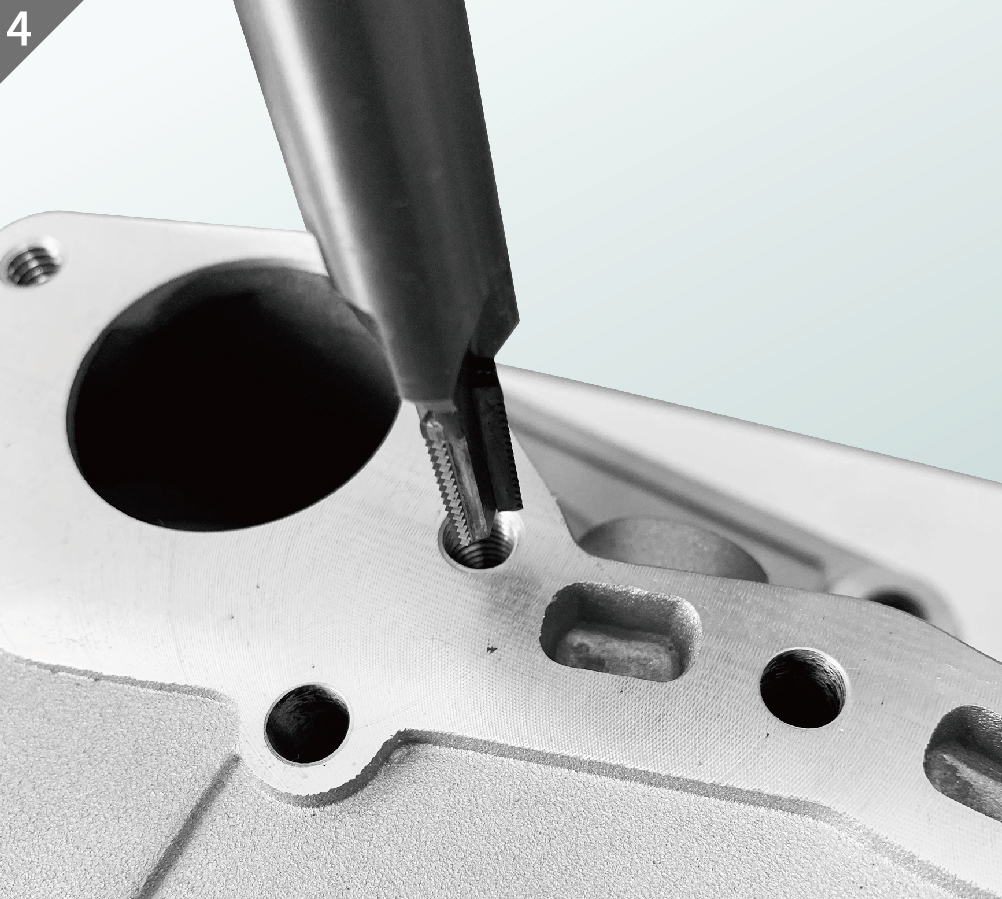

- Intake/exhaust valve guides

- Gear bushings

- Wheel bearings

- Oil injection nozzles

- Output shafts

- Automotive brake valves

- Brake discs

- Ball cages

- Differentials

- Engine

- Oil sump

- Turbocharger Housing