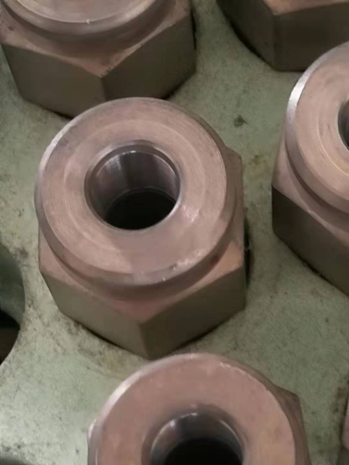

The relief valve, also known as the safety valve, is mainly to control the safety of pressure pipelines and containers, once the pressure exceeds the prescribed range, the safety valve tops open and discharges a portion of the gas, controlled within the safety range to ensure that the diesel engine will not be too high pressure can not withstand two safety accidents.

When machining diesel engine relief valves, the commonly used workpiece material is 20Cr, a type of quenched steel with a material hardness of HRC 55. but the quenched parts have high hardness, high strength and plasticity close to 0.

WSS PCD and CBN tools combine a high standard of chipping resistance and wear resistance for all finishing situations in hardened steel.

Tool drawing number: 072231

Workpiece name: Diesel engine relief valve

Workpiece material: 20Cr

Material hardness: HRC55

Workpiece size:φ6.9

Roughness:Rz5

Machining method: Turning, dry cutting

Machining process: Hard turning bore

Available brands: domestic

Note: More cost effective than current knives