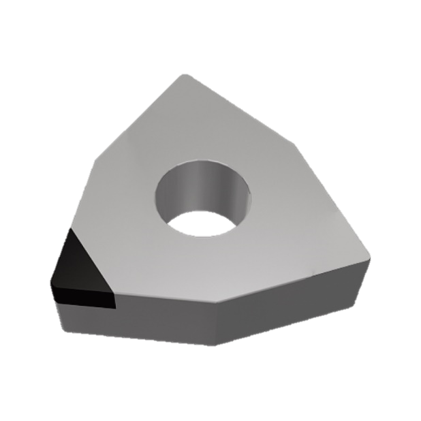

The differential gear ring is made of hardened steel with an inner layer of automatically assembled motor vehicle differential gear ring parts. In the turning process, the key to the production and processing challenge lies in the continuous turning process. The surface quality and dimensional tolerances must be in accordance with customer specifications and the use of high-end customised combination tools such as turning inserts, alloy drills and reamers is essential for the production process.

Highly efficient, safe and reliable turning of internal diameters and faces with low cost and time, ensuring high productivity in external and face turning, rapid, high quality and stable mass production of bores, accurate boring for the highest surface quality and efficient turning of internal diameters and backs.

Machine type: DMG MORI

Workpiece name: Differential

Workpiece material: QT700

Roughness: Ra1.6

Machining method: continuous, intermittent

Machining parameters:

VC: 300-350m/min

f: 0.15mm/rev

Ap: 0.5 mm

T/L (life): 50 pieces

Tool drawing number: 070561

Workpiece name: Differential gear ring

Workpiece material:20CrMnH

Workpiece size:φ106φ149

Roughness:Ra1.6

Machining method: Turning, air cooling

Machining process: Fine-turning of bore and end face

| | |

| | |

| | |

| | |

| Bore 0.1mm End face 0.15mm | Bore 0.1mm End face 0.15mm |

| | |