Automotive engine parts machining solutions

Engines are the heart of automotive power and WSS solutions and tools for aluminium and cast iron engine components rely on the practical application of a team of technical experts and a commitment to constantly optimise and improve tools to create a better standard of workmanship.

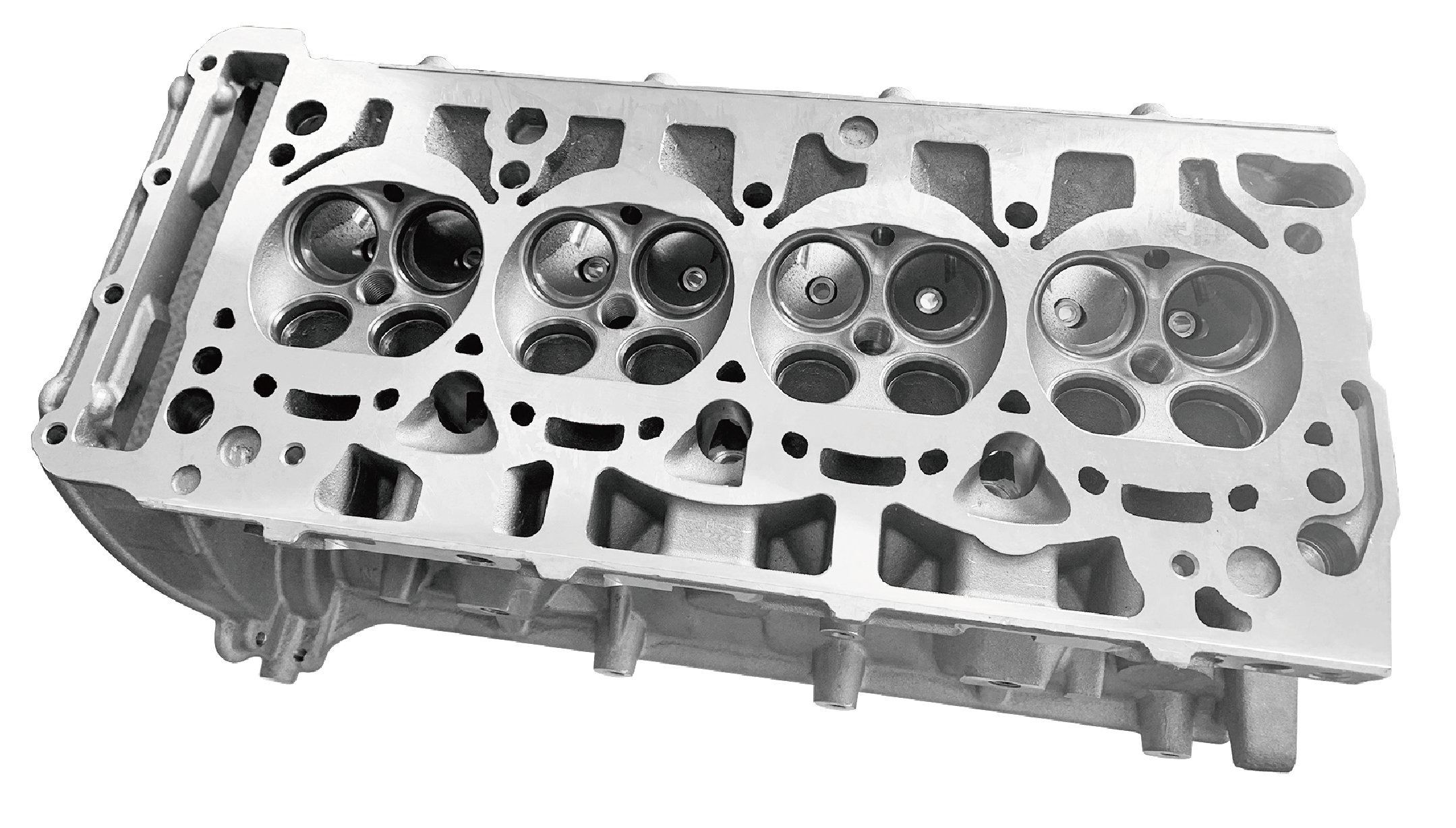

Aluminum cylinder heads for engines

Cylinder heads are complex to manufacture and are an important component of the engine, and their quality greatly affects the performance of the vehicle. WSS face milling cutters and CBN chamfering cutters guarantee consistent performance and offer cost-effective machining solutions.

Cylinder head large surface machining

WSS face mills are equipped with safe tool holders and robust inserts for efficient finishing face mills to significantly increase machining efficiency.

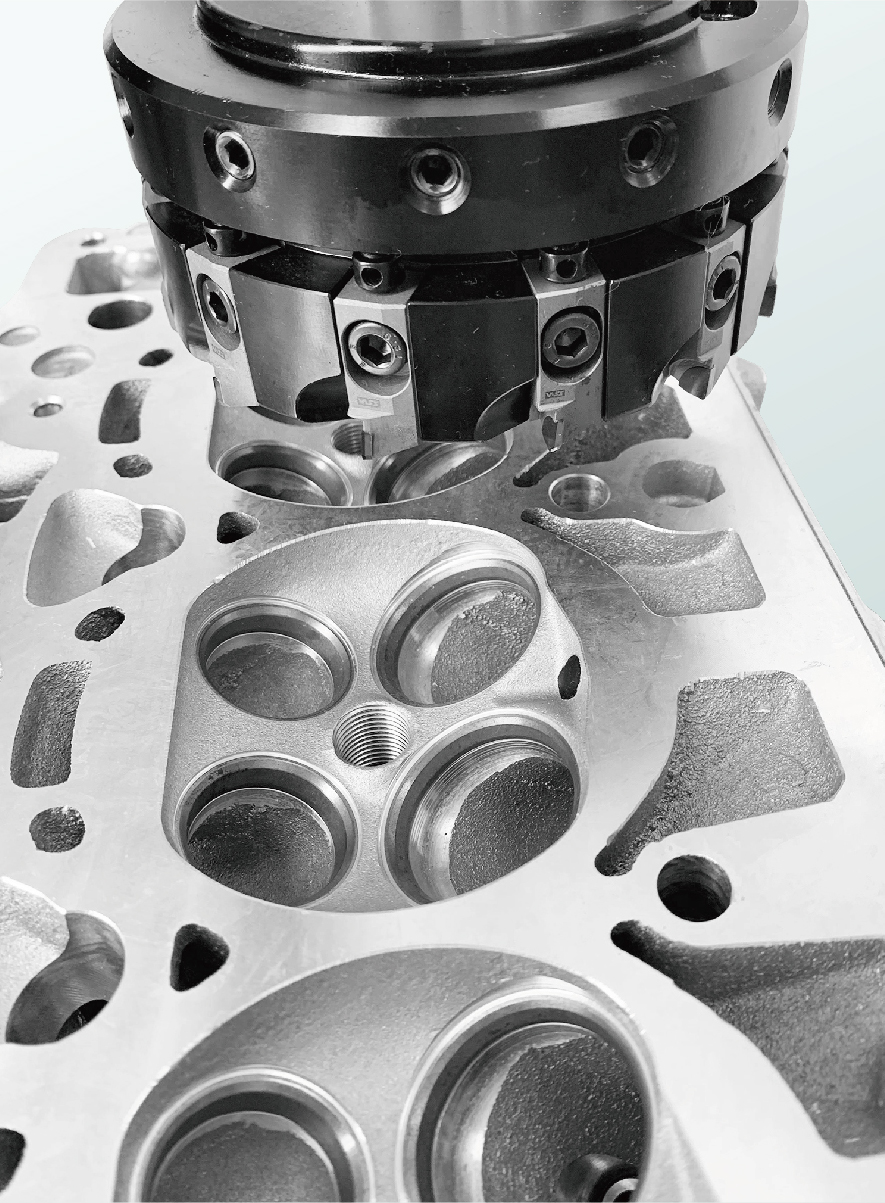

CBN chamfering tool for precise and smooth machining of valve seats, guaranteeing a high quality surface finish

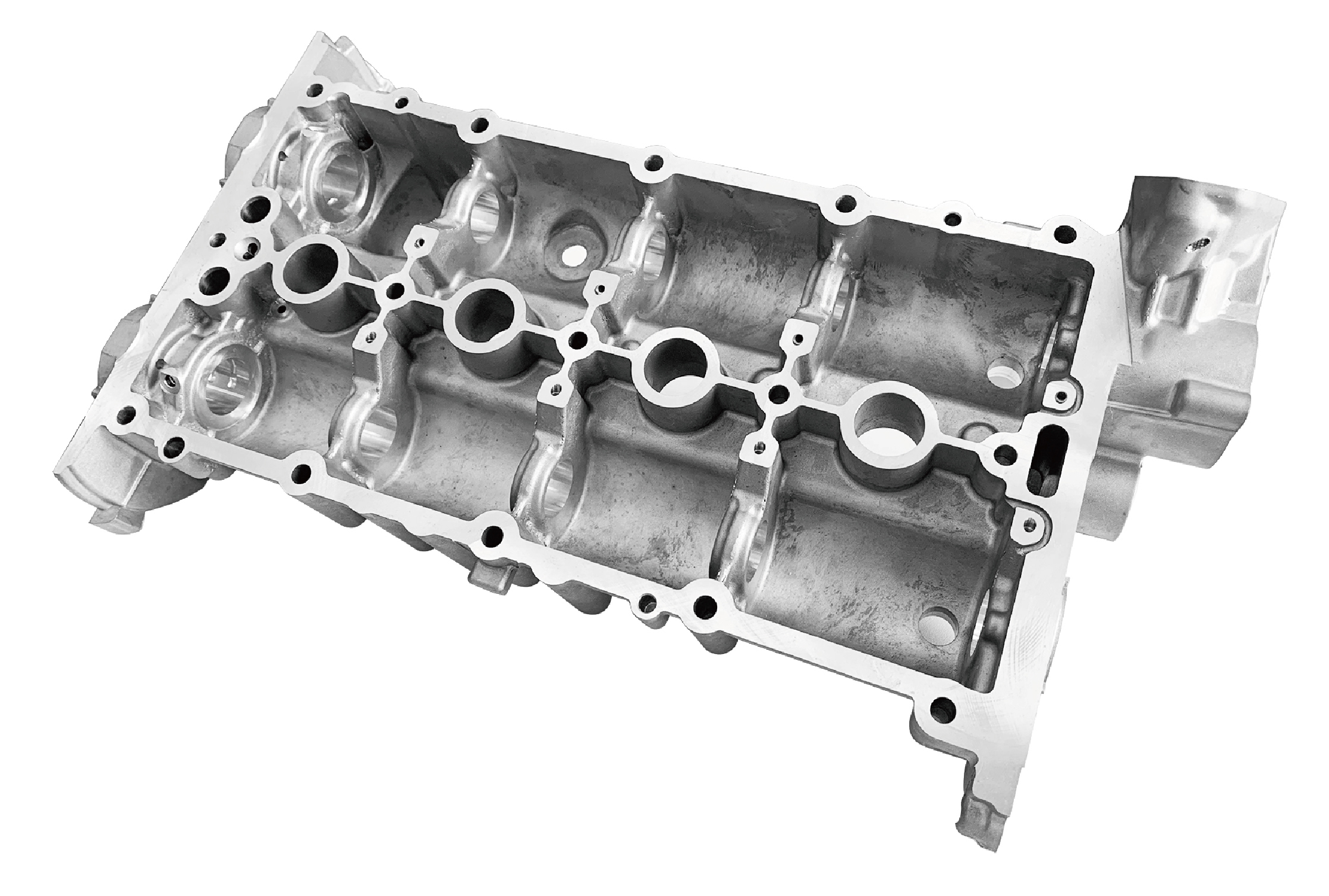

Aluminum cylinder head housing for engines

The quality of the cylinder head housing plays an important role in the proper functioning of the cylinder head. The use of WSS face milling cutters for consistent finishing of the cowling surfaces ensures surface quality while increasing machining efficiency and creating more value for the customer.

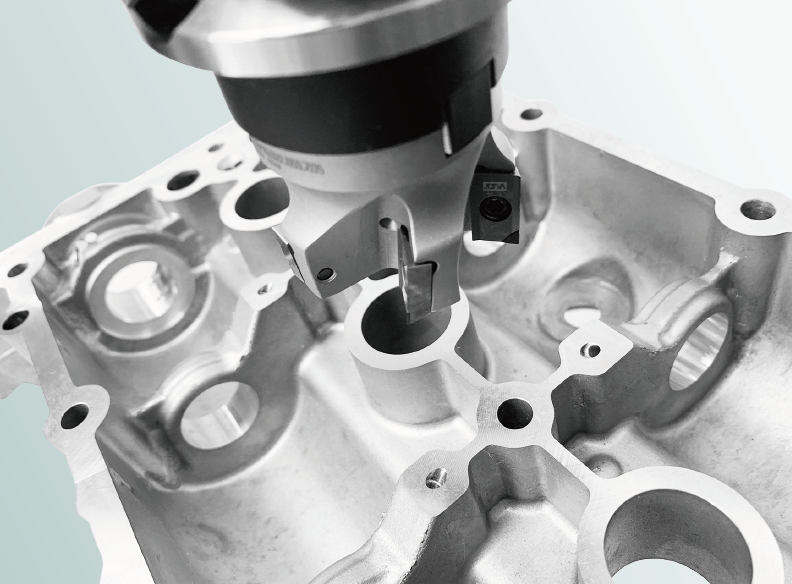

WSS face mills (APKT) for high-speed finishing of aluminium parts, smooth face milling for excellent surface quality and high feed rates

Workpiece name: Rear cylinder body

Workpiece material: HT250

Material hardness: HB210

Workpiece diameter: φ35

Roughness: Ra0.8

Machining method: Fine boring, continuous

Machining process: Finishing

Available brands: Domestic tools

Note: Test results exceed domestic tools and meet customer requirements