?Indexable inserts are used at all major cutting points, and

most are ISO inserts for easy management.

?Composite tools tailored to the automotive braking system,

which are highly efficient and significantly reduce manufacturing

costs.

?Precise groove profile inserts, exclusively manufactured for

non-standard inserts, which perform well in cutting.

?Continuously optimised complete solutions, fully implemented

to improve efficiency and save costs throughout manufacturing.

?Meet the high efficiency. requirements of top automotive

component manufacturers.

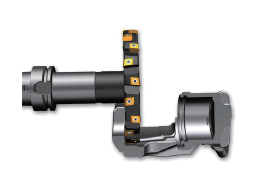

?Tangential triple-edge with dense tooth

design to achieve high cycle times and

low costs. Also available as a

flush-mounted triple-edge tool for

low-power machines

?Advanced insert materials with multiple

groove and fillet options

?Low cost per part and good machining

stability

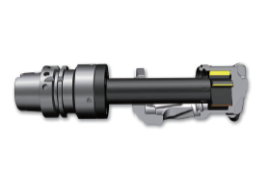

?ISO standard insert design for rough boring

?Inclusion of negative tool inspection inserts

?Economical and greatly improved process safety

Master Cylinder Bores Rough Boring

Dust-proof And Sealing Groove Processing

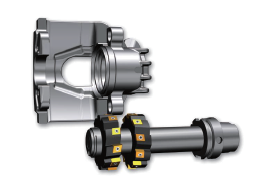

?Cap and saw insert configuration for

different workpiece diameters

?Composite body material, unique

insert design and excellent vibration

damping for stable machining and

longer tool life

?ISO standard insert design

Multi-edged clamp construction for

?efficient and economical use

Master Cylinder Bores Fine Reaming

?High efficiency and process stability of the

multi-edge reamer for optimum efficiency

?3D adjustable shank for reamer mounting

accuracy, ensuring machining accuracy and

tool life

?The tangential, dense-tooth design of the

milling tool plate allows for simultaneous

machining of the upper and lower faces for

efficient machining

?Set of milling high-efficiency cutters for easy,

simple and reliable operation

?Multi-flute inserts with high cost performance

?The combination of negative and profiled

inserts with precise end-slot line

engagement ensures extremely high

machining efficiency

?The inserts are all screw-locked for easy

handling