With the high hardness of dense wind turbine gear materials, the higher wear resistance and stability of superabrasive tools can help you improve machining efficiency, reduce the cost per part and achieve higher profitability in wind turbine component manufacturing.

Wind turbine gearboxes are made up of high strength and hardened steel components. The machining of the components is essential in order to achieve higher torque densities and greater efficiency in the gearbox.

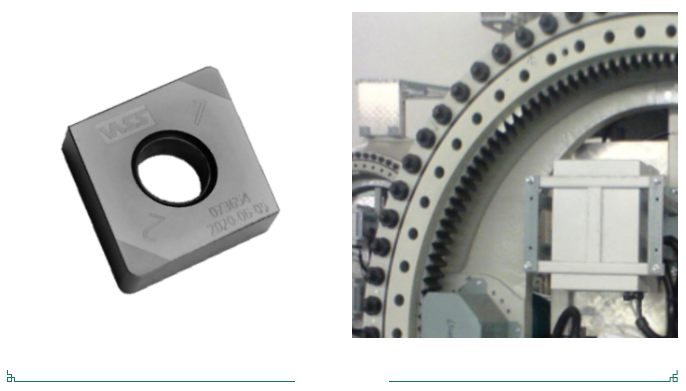

Wind power gearbox gear machining case

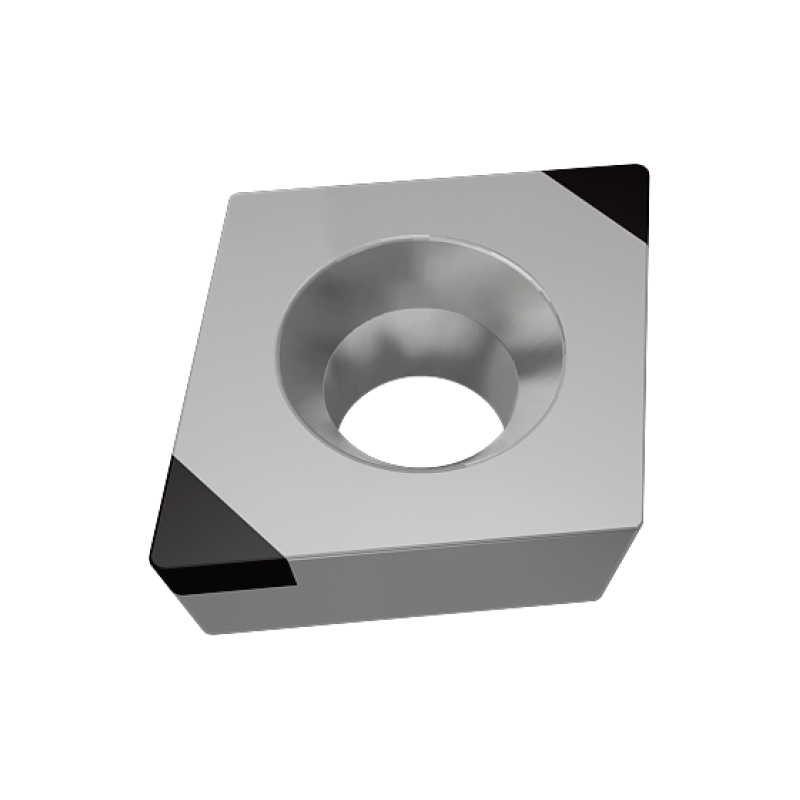

Large gear endface machining

WSS CBN tools enable high speed cutting with high hardness and wear resistance in the finishing process of high hardness parts, with a lower coefficient of friction to improve the surface quality of the workpiece being machined.

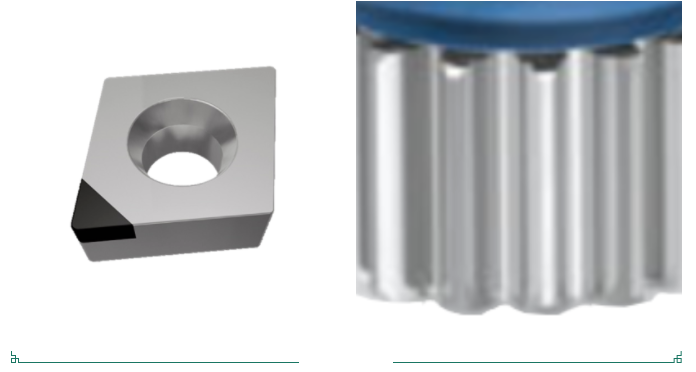

Planetary gear bore machining

The imported head material enables high metal removal rates to be achieved at higher cutting speeds, significantly improving machining times and machine availability for large gear bore machining, saving you more time and costs.

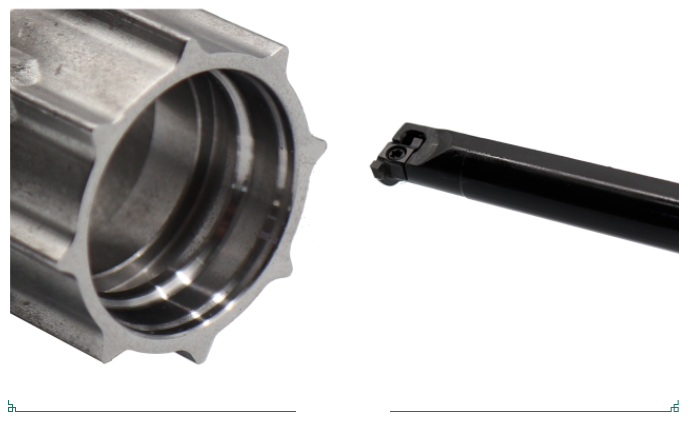

The continuous cutting internal groove cutter is capable of high precision cutting. The stable tool performance and sharp edges prevent vibrations during machining and give a consistent surface quality of the internal groove.

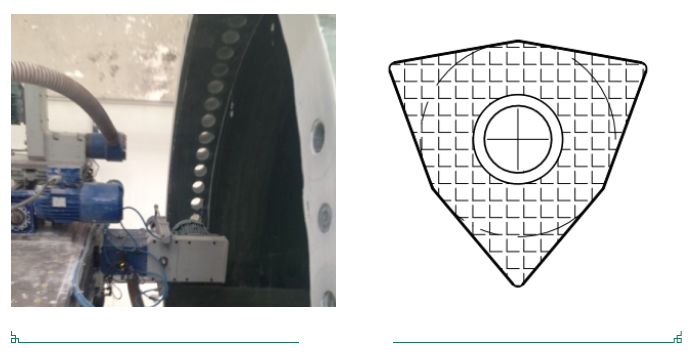

Wind turbine blade drilling and machining

The material properties of PCD make it ideal for machining composite materials, making it an excellent choice for improving machining efficiency and quality.

|Precision · WSS TOOLS

|Focus on superhard tool machining solutions