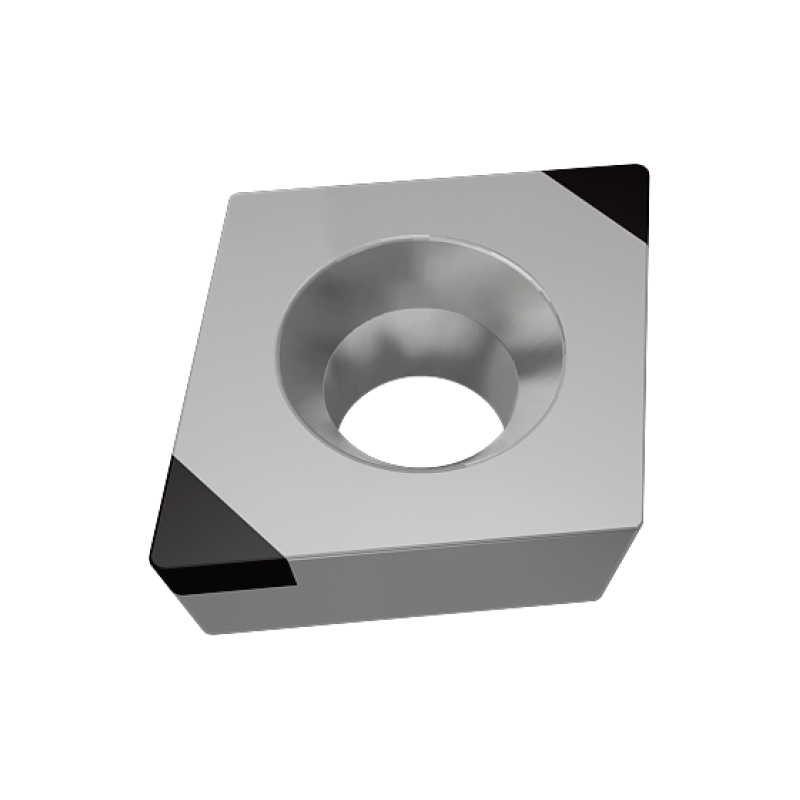

?Indexable inserts at all major cutting points, mostly ISO

inserts for easy management

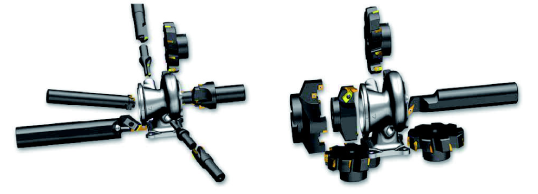

?Special compound tools tailored to the automotive

turbocharger system, which are highly efficient and

significantly reduce manufacturing costs

?Specific insert options, both ISO or non-standard

customised inserts have excellent performance in

mass production

?Continuously optimised complete solutions, fully

implemented and have been proven for increased

efficiency and cost savings throughout manufacturing

Ductile iron, high nickel cast iron, heat resistant stainless steel

Operating temperature: About 850°C (diesel engines)

About 1050-1200℃ (gasoline engine)

Machining interference, tool shape is

exceptional and difficult to reach

machining positions

High nickel material is an immense

challenge for tool life

?Specialised efficient coatings

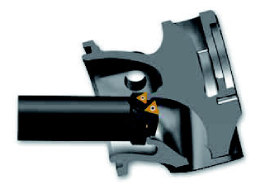

?Efficient reaming and turning

formed in one operation

?Easy insert management with

ISO standard inserts

K-line Reaming And Turning

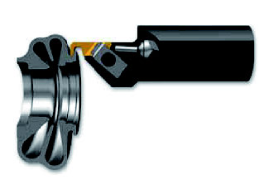

Shallow Hole Drilling + Chamfering And Orifice Forming

?Holes up to 20 mm are drilled and chamfered

in one operation

?Reduced tool wear and greatly decreased

costs compared to hardened tools

?Customised tools grooving on end face

in one process

?High longevity and dimensional stability

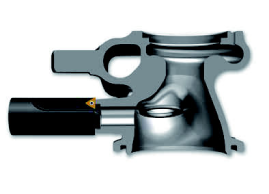

?Valve bore and flat machined in one operation

?Flange face milling and back-scraping

of the surface

?Light and fast cutting and high efficiency

?Vibration-resistant carbide

toolholder

?Special tool body material with

efficient ISO inserts, perfect for

fine turning