- milling_bz

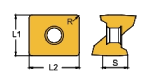

- 圓刀片銑刀

- milling_fb

- 球頭銑刀

- milling_xx_title1

- 球頭精銑刀

- milling_xx_title2

- 45°倒角銑刀

- milling_xx_title5

- 45°銑刀

- milling_xx_title6

- 43°銑刀

- milling_xx_title3

- 90°銑刀

- milling_xx_title4

- 89.5°銑刀

- 玉米銑刀-SP

- 鍵槽銑刀

- 玉米銑刀-AP/AD15

- T型槽銑刀

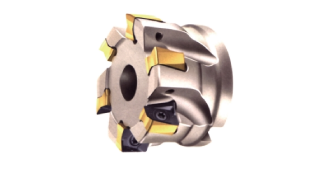

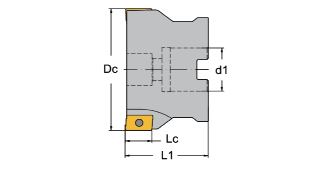

- 模塊式玉米銑刀

- 三面刃銑刀

- 微痕玉米銑刀

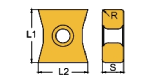

- 快進給銑刀

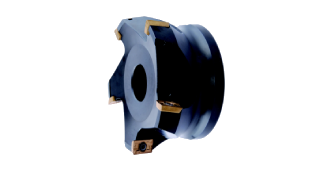

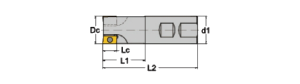

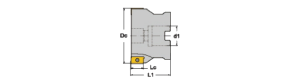

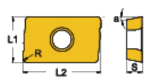

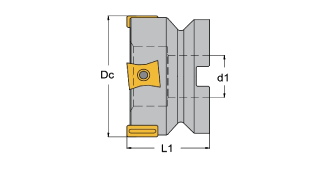

- 模塊式面銑刀-圓刀片

- 多刀片兼容銑刀

- 模塊式密齒面銑刀

- 密齒銑刀-89.5°

- 模塊式面銑刀-TP

- 密齒銑刀-75°

- 鋁合金面銑刀

- 密齒銑刀-45°

- 模塊式三面刃

- motor_vehicle1

- motor_vehicle3

- motor_vehicle4

- motor_vehicle5

- motor_braking

- motor_vehicle7

- motor_vehicle8

- motor_vehicle9

- motor_vehicle10

- motor_vehicle11

- motor_vehicle12

- motor_vehicle13

- motor_vehicle14

- motor_vehicle15

- motor_vehicle16

- motor_vehicle17

- motor_vehicle18

- motor_vehicle19

- motor_vehicle20

- oil_pan

- motor_turbocharger